Introducing large building stones + the best purchase price

the properties of large building stones are that they are usually porous and sedimentary and also are commonly used as magic stones to construct different types of buildings

In order to assess the quality of each stone as a building material, it is important to analyze its specific petrographic characteristics and physical properties, as these properties affect its behavior when exposed to degrading agents

We selected six stones with different petrophysical properties commonly used in Spain as building materials

Two limestones with high porosity and significant structural differences achieved the worst results

The bioclastic limestone from Santa Pudia exhibits poor mechanical properties, while the micrite from Huesca responds the worst to water flow

Both sandstones performed better

They have medium porosity, similar texture and some compositional differences

Uncastillo’s limestone sandstones are inferior in hydraulic and mechanical properties and are therefore not as durable as Villaviciosa’s siliciclastic sandstones

The most valuable stones in terms of water behavior and mechanical properties are Boñar’s crystalline dolomite and Albox’s travertine, both of which have relatively low porosity

Gems are classified into low, medium and high quality

Limestone with high porosity and low consistency shows low quality

Sandstones with similar porosity but different compositions exhibit moderate quality

Stones with low porosity show the highest quality

Differences in the composition and distribution of pores can affect quality

The criteria for selecting stone for structural purposes are cost, fashion, ornamental value and durability, although the latter characteristic is often overlooked or overlooked

Costs are largely influenced by shipping costs, difficulty of extraction and cutting, and the ornamentation and durability of the stone

The type of stone coating affects the cost, especially for stone from igneous rocks

For the mentioned ideas building stones are considered magic stones in all fields of use

properties of building stones

Strength and durability are essential properties of building stone

The compressive strength of a stone determines its ability to withstand the weight of stacking on top of each other

A building stone’s compressive strength should be 60 to 200N/mm2

Porosity is the ratio of pores (micropores) in a stone to its total solid volume

Each of the three stone groups has a different pore and hair structure

A dense, dense stone with few or no pores inside

An important feature of sedimentary rocks is their porosity

Pores are natural holes in the stone that allow liquids such as rainwater to enter and exit the fabric

Maintaining rock durability requires fluid to flow freely through the rock, and it is not always desirable to stop this flow by using the wrong mortar mix or injecting an inappropriate synthetic fluid

However, very high porosity can allow excess corrosive fluids (such as acidic rainwater) to enter and cause severe rock damage

Analysis of thin slices of rock can identify where such problems may occur

Most durable sedimentary building stones typically have moderate porosity

Related to the porosity of a stone is its permeability

This is the degree to which pores and capillary structures are interconnected throughout the stone

These nets, their size, structure and orientation affect the degree and depth to which moisture, vapors and liquids are absorbed into the stone or migrate from the substrate through the capillary action of the stone

Permeability increases when the stone is highly fractured or the granular material is soft or granular

Despite low porosity (low percentage of voids), certain kinds of stone can have high permeability well-defined and interconnected network of pores

The size and shape of pores, as well as hair structure, vary among stones and are important factors in stone decay

large building stones

building Stones that are large is one of the oldest building materials in the world, valued for its strength and durability

In ancient times, it was chosen for its abundance: as a natural material, it was readily available and reliable

But there’s a lot more to this material than you might think, and there’s a reason architects continue to build with it, around it, and within it

The structures on this list demonstrate the ability of stone to change shape; it can be used in its raw form or polished for a more polished finish

No wonder it is the material of choice for important monuments and buildings such as places of worship, castles and palaces, as it outlasts nearly all other materials

Stone is one of the oldest building materials in the world, valued for its strength and durability

In ancient times it was chosen for its abundance: as a natural material, it was readily available and reliable

But there’s more to the material than one might think, and there’s a reason architects continue to use it, around it, and build within it

The structures on this list demonstrate the ability of stone to change shape; it can be used in its raw form or polished for a smoother finish

No wonder it is the material of choice for monuments and important buildings such as places of worship, castles and palaces, as it outlasts nearly all other materials

Before concrete became the main building material, heavy retaining walls and walkways for bridges and canals were built with a variety of stones: granite, bluestone, medina, and limestone, among others

Mason hand carves each block and pushes it into place, creating a work of art that will last for hundreds of years

expensive building stones

In an era when advanced resin and wood fiber materials are increasingly being used in residential project development, home builders are still using the following building stones in expensive homes

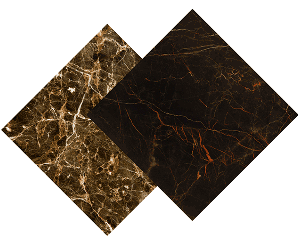

Marble

Marble is a type of limestone that has undergone geological processes by combining various crystalline minerals

Marble floors are the epitome of luxury flooring

They require careful installation and dedicated maintenance, but their palatial appearance makes them worth the investment and maintenance

White marble floors are perfect for rooms and other living spaces that will wow guests

Granite

Granite is a popular choice for kitchen and bathroom countertops because of its beautiful and durable texture

This natural stone is not as slippery as marble, and granite is easy to care for

Slate

The rustic look of slate makes it ideal for patios, pool areas, summer kitchens and garden paths

Slate is available in tiled forms, but irregular sections can be used to decorate columns, sketches, and walkways

Red slate is recommended for homes built in Spanish Colonial or Mediterranean Revival residential architectural styles

Limestone

When limestone is cut, smoothed, treated and sealed, the final look is shiny and unique, especially when the outlines of shells and coral can be seen on the surface

Like marble, limestone is very porous and requires special care

Travertine

Travertine is a kind of limestone that has not completely completed the metamorphism process and turned into marble

It is crystal clear and colorful

Irregular pieces can be used for decorative architectural elements such as cladding columns or back sketches

Quartzite

When quartz-rich sandstone is subjected to tectonic stress, the resulting iron oxide mixes with various minerals to form quartzite, a hard metamorphic rock that can be processed to make polished floor tiles or cut for a crystalline, rustic look

largest building stones

A team of German and Lebanese archaeologists has just discovered the largest man-made building stones ever found

The block, which was discovered in a limestone quarry in Baalbek, Lebanon, measures 64 feet by 19

6 feet by 18 feet and weighs about 1,650 tons, according to Gizmodo

The largest stone to date that has been moved by hand alone (i

e

without the use of animals or machines) is the Thunder Stone, a huge granite boulder that serves as the base of the famous statue of Peter the Great Bronze Horseman in St

Petersburg, Russia

In Lebanon, the Bekaa Valley, about 1,170 meters above sea level, is known as Baalbek, or Heliopolis in Roman times

Baalbek is an ancient site that has been in use since the Bronze Age and is at least 9,000 years old, according to evidence found during a German archaeological expedition in 1898

Baalbek is an ancient Phoenician city named after the god Baal

The name “Baal” means “Lord” or “God” in Phoenician

Legends abound around Baalbek, with some mentioning that Baalbek was the place where Baal first arrived on Earth, so ancient alien theorists believe that the original construction was likely as a god using Baal to “land” and “take off” built on the platform

Part of the reason for this suggestion is that Heliopolis was built on a huge platform, probably built in pre-Roman times, for the original temple or city of Baal-Baalbek

If you look at this photo, it is clear that different civilizations have built different parts of what is now called Heliopolis

However, aside from theory, the real purpose of this structure and who built it is completely unknown

tests on building stones

various tests are done to understand the presence of calcium carbonate in building stones

Take a sample of stone that weighs about 50-100 grams

Place it in a 1% hydrophobic acid solution and leave it there for 7 days

The solution was stirred at intervals

A good building stone will keep its edges sharp and its surface free of dust at the end of this period

If the edges are cracked and dust forms on the surface, indicating the presence of calcium carbonate, the stone will have poor weathering quality

This test is usually performed on sandstone

Stone samples were cut into cubes measuring 40 x 40 x 40 mm, the dimensions of which were finely machined and finished

The maximum number of samples to test is three

The sample must be placed in water for approximately 72 hours prior to testing and then tested under saturated conditions

The bearing surfaces are then covered with plywood plaster of paris approximately 5mm thick

The load is applied axially to the cube in the crushing tester

The loading speed is 140 kg/cmq per minute

The compressive strength per unit area of the stone is the maximum load at which the sample is crushed or fractured divided by the area of the bearing surface of the sample

Immerse the stone samples in water for 24 hours

It was then placed in the freezer at -12°C for 24 hours

It is then thawed or heated to atmospheric temperature

This should be done in the shade to avoid any effects due to wind, sun, rain, etc

Repeat this process several times, carefully observing the behavior of the stone

My company has for decades been the lead in both supply and export of building stones to all countries through the entire continents and hence is kindly honored to invite all dear customers and traders to join us in world trade of building stone and experience the best purchase ever in your life